Benefits of Pre-Insulated Polypropylene (PPR) Pipe

Reduced heat/energy loss.

Optimization of energy resources.

High efficiency.

General Characteristics

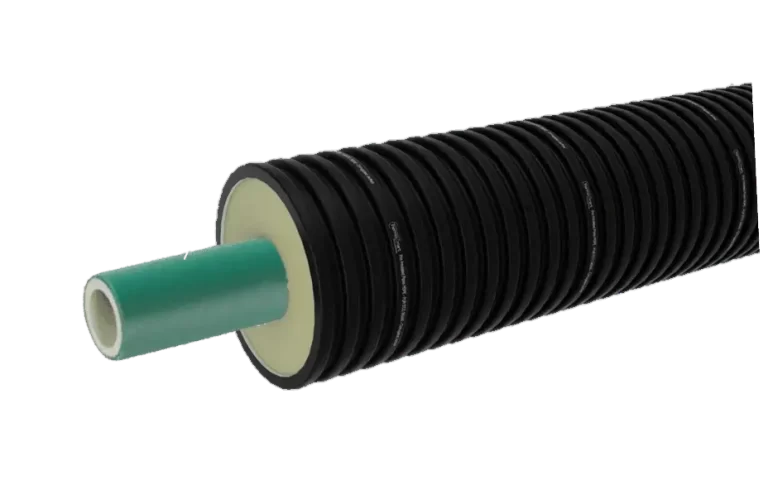

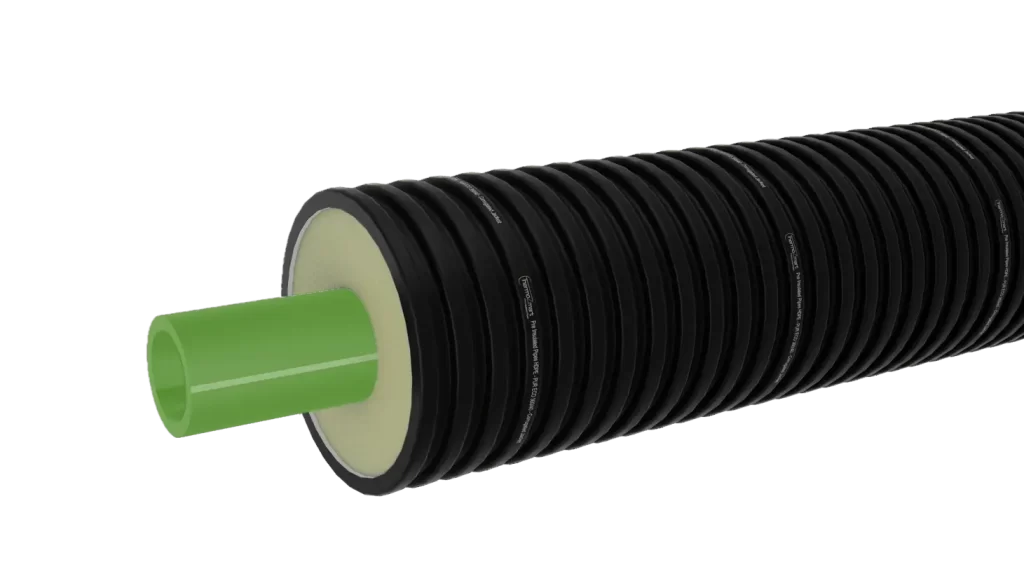

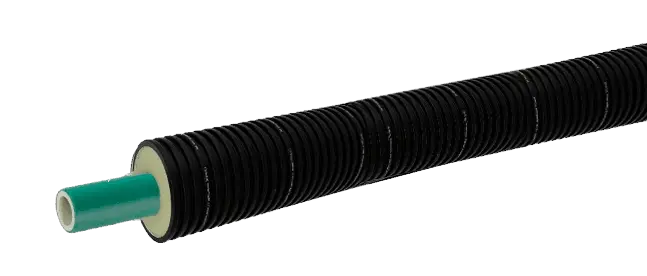

The pre-insulated Polypropylene (PPR) pipe is a highly efficient solution for liquid transport in industrial applications. This system is manufactured with high-quality materials under the strictest production standards, ensuring its excellent performance in various applications, including hot and cold water systems, urban heating, district heating/cooling, and VRF/VRV systems.

Thanks to its innovative high-pressure injected rigid foam thermal insulation of PUR/PIR and its mechanical protection, the pre-insulated Polypropylene (PPR) pipe effectively reduces heat/energy losses and optimizes energy resources, offering an ideal solution for the refrigeration industry and other fields. Additionally, its corrugated and impact-resistant structure provides additional protection against wear and potential mechanical deformations, ensuring its durability and strength.

- Technical Data

- Diameters

- Application-specific Solutions

Two-component high-quality insulation: polymeric isocyanate foam and cast ECO 360-40. This insulation leads the market due to its 99% closed cell structure, providing minimal thermal conductivity and high resistance to moisture absorption. Additionally, our insulation system is 100% ECO-FRIENDLY, as it is free from CFCs and HCFCs, and it uses the ECOMATE expansion agent, which does not harm the ozone layer. This product is also VOC-free, making it a 100% Eco-Friendly Expansion Agent classified by SEMARNAT, complying with the Montreal and Kyoto Protocols.

| General Features | Units | Limits | Methods |

|---|---|---|---|

| Packed Density | Kg / m3 | 45 – 50 | NMX-C126-82 |

| Closed Cell Content | % | >94 | ASTM D 2856 |

| Initial Thermal Conductivity | W / °C m | 0.0220 | NMX-C181-1984 |

| Dimensional Stability 1 week at -20 °C | %Vol | <0.6% | UNI 809 |

| Compression Strength | psi | 42 | UNI 6350 |

| Water Vapor Permeability | ng / Pa s m | 0.1 | NMX-C-210-1984 |

Pipe Diameter and External Diameter Table (after injecting PUR thermal insulation)

| Central Pipe (in.) | Outer Jacket (in.) |

| 1/2″ | 3″ |

| 3/4″ | 3″ |

| 1″ | 3″ |

| 1 1/4″ | 4″ |

| 1 1/2″ | 4″ |

| 2″ | 6″ |

| 2 1/2″ | 6″ |

| 3″ | 6″ |

| 4″ | 8″ |

| 6″ | 10″ |

| 8″ | 12″ |

| 10″ | 14″ |

| 12″ | 16″ |

| 14″ | 18″ |

| 16″ | 20″ |

| 18″ | 24″ |

| 20″ | 24″ |

| 24″ | 30″ |

- Sistemas de calefacción y refrigeración en edificios residenciales y comerciales.

- Sistemas de agua caliente y fría para uso doméstico y comercial.

- Sistemas de distribución de agua potable.

- Sistemas de transporte de fluidos químicos y corrosivos en la industria química.

Each solution is designed to optimize energy resources and reduce heat/energy losses, resulting in significant cost savings and increased efficiency in the production process.

Pipe Component

The pre-insulated Polypropylene (PPR) pipes and fittings consist of three main components:

- High-quality central pipe:Ensuring safe and effective liquid/fluid conveyance.

- High-pressure injected rigid polyurethane foam insulation:Our PUR insulation effectively reduces heat/energy losses and optimizes energy resources, making it an ideal solution for the refrigeration industry and other fields.

- High-quality outer protection: We offer different options for the outer protection of our pre-insulated pipe, including PVC, anti-corrosive polyethylene tape, and corrugated polyethylene pipe (PAD). This ensures the mechanical protection and durability of our product.

Mechanical Protection Options

Manufactured with high-quality materials under strict production standards, this pre-insulated pipes and fittings system is designed to deliver excellent performance in applications such as chilled/cold water systems, hot water systems, district cooling/heating, industrial glycol cooling, refrigeration, VRF/VRV, among others.

Thanks to its innovative high-pressure injected rigid expanded PUR/PIR foam thermal insulation and mechanical protection, the ThermoZmart Pre Insulated Pipes and Fittings System effectively reduces heat/energy losses and optimizes energy resources, making it an ideal solution for the refrigeration industry and other fields.

Hydraulic PVC:

Interior of the building, without UV protection.

Smooth PEAD:

Exterior of the building, with UV protection.

Corrugated PE:

Exterior of the building, with UV protection, for buried/underground installations.

Benefits of Thermozmart Pre-Insulated Pipes:

- ENERGY SAVINGS by reducing heat losses.

- SAVINGS in maintenance, by preventing insulation from coming into contact with installation-specific situations.

- Reduction in the risk of condensation due to the rupture of unstable vapor barriers.

- Prevents external accumulation of fungi and bacteria.

- Mechanical protection and vapor barrier.

- Optimal density in polyurethane insulation.

- Customized solutions, we adapt to the requirements of your system and/or project.

- The outer jacket has a UV-resistant element (Polyethylene).

- Lower structural weight..

- High resistance to impact from external elements to your installation.

Frequently Asked : Questions (FAQs)

ThermoZmart is the brand of the Pre Insulated Pipes and Fittings System configured, designed, and manufactured by Teksol Group Solutions.

As part of its supply strategy, Teksol has different sites from which the pre-insulated pipe and fittings system is supplied. Therefore, knowing the location of your project, the best origin location for system supply to the destination port will be designed.

- Chilled/cold water

- Hot water

- Water with glycol

- Ammonia

- Refrigerant gas, variable volume

- District cooling and heating

Pre-insulated pipes with corrugated mechanical protection, as the grooves of the corrugated mechanical protection of Polyethylene allow it to adapt to the irregularities of the terrain, without the need for a concrete bed. It is recommended to analyze the central pipe to be used depending on the application.

- Installation time, as three products are installed in one solution. -

- Reduction of labor.

- Reduction of condensation risks due to oversight when installing traditional systems or unintentional ruptures of the vapor barrier; condensation can generate both heat losses and structural damage to the building.

- It is recommended to use a mechanical protection made of Polyethylene.

The insulating power of a material is measured through the evaluation of its thermal conductivity, or "K" Factor. This value indicates the amount of heat that a sample of a certain material allows to pass during a certain time, with a temperature differential between one side and the other.

- PVC C40/80, PPR, Steel, PB-1, PEX

- CPVC, PPR, PE, Copper

- PEAD

- Steel

- Copper, Pex Al Pex

These are the main ones, however, if you have any specific requirements, please write to: sales.intl@teksolgroupsolutions.com; and a technical advisor will guide you.

- PVC C40/80

- CPVC C80

- PPR (Polypropylene)

- Steel

- ThermoZmart is the brand of rigid pre-insulated pipes manufactured by Teksol, however, for more than 15 years we have handled different solutions in pre-insulated pipes, including flexible ones. Therefore, please send us an email and we will gladly assist you: intl@teksolgroupsolutions.com

- No, ThermoZmart is the name given to the pre-insulated pipe and fittings system solution. Teksol does not manufacture central pipes, these are acquired from different manufacturers worldwide, with the highest quality standards.

- This depends on the type of central pipe, but as an example, we supply PVC/CPVC pipes in lengths of 5.8/6 meters.

The vapor barrier is an element that prevents the generation of interstitial dampness or condensation. It is a very effective and inexpensive method, and, in addition, the materials used in the construction may themselves perform this function.

Some examples:

- Elements integrated into thermal insulation, such as:

- Rubbers, surface layer

- Polyolefins, integrated throughout their mass

- XLPE, aluminum foil

- Granular glass, blanket

- Fiberglass, aluminum foil

- Pre-insulated pipes, PVC/PE

- It is an element that prevents the passage of humid air through the cells of a material, seeking to avoid condensation problems and excessive energy consumption.

- Examples:

- Hydraulic PVC,

- PEAD

- Aluminum foil

- Stainless steel