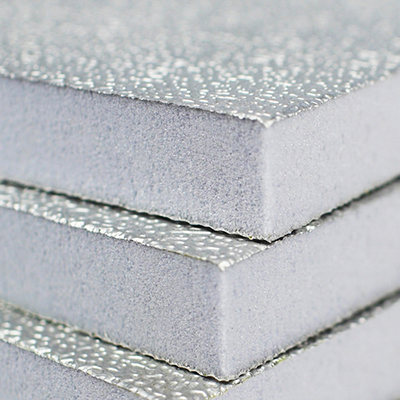

Description:

Panel de espuma rígida de poliisocianurato (PIR) revestida por las dos caras con aluminio gofrado. Debido al espesor de la lámina de aluminio (>50 µm) el producto puede ser considerado como barrera de vapor.

Prácticamente nula absorción de agua gracias a la estructura de celda cerrada del polímero y al recubrimiento de aluminio.

Excelente coeficiente de conductividad térmica.

| Panel thickness | Apparent density | Aluminum thickness | Aluminum type | |

| IR ALU 20/35 | 20 mm | 35 kg/m3 | 60 µm | gofrado |

| PIR ALU 30/35 | 30 mm | 35 kg/m3 | 60 µm | gofrado |

| Thermal conductivity coefficient λi, (7d 10ºC) (W/mK) | 0.022 |

| Declared thermal conductivity coefficient λD, 10ºC (W/mK) | 0.023 |

| Compression resistance (kPa) PIR ALU 35 [blue color] | 300 ±30 |

| Resistencia a la compresión (kPa) PIR ALU 45 [color rosa] | 425 ±50 |

- Sheet of: 3.0 x 1.2 m = 3.6 m2 of 20 mm in packages of 12 units.

- Sheet of: 3.0 x 1.2 m = 3.6 m2 of 30 mm in packages of 10 units.

Conductos HVAC en aluminio Pre-aislados Strip System®PIR-ALU

ESPECIFICACIÓN PARA PROYECTOS

Conductos hvac en aluminio pre-aislados para suministro y retorno de aire y ventilación

El contratista debe suministrar e instalar conductos fabricados con paneles tipo sándwich de aluminio pre-aislados con espuma rígida de PIR (Poliisocianurato) libre de CFC y HCFC con una lámina de aluminio puro gofrado de 60µm de espesor en cada cara y con certificado de no proliferación microbiana.

El espesor del panel será de 20mm para conductos instalados en el interior y de 30mm para conductos a la intemperie o de gran tamaño.

La espuma PIR debe tener una densidad media de ±35 kg/m3 y cumplir con los requisitos de aislamiento del RITE (Reglamento de Instalaciones Térmicas en los Edificios).

Todos los materiales utilizados y los conductos terminados deben cumplir con las exigencias del RITE y con la norma europea EN 13403 para “Conductos no metálicos” y otras EN de referencia en ella mencionadas.

Los conductos serán construidos con base a los Protocolos y manuales de trabajo facilitados por el fabricante. Por lo tanto, hacen parte de esta especificación los requerimientos dados por los reglamentos, normas y recomendaciones aquí mencionadas.

Documentación y gestión de calidad

Antes de iniciar los trabajos, el contratista deberá aportar todos los ensayos y certificados requeridos en la norma EN 13403 y en especial los certificados de reacción al fuego europeo EN 13501-1 (Euroclase B-s1,d0) y/o americano ASTM E84-15 (Class A FD/SD ≤25/50). Al finalizar los trabajos el contratista deberá aportar los formularios cumplimentados de los Protocolos de trabajo. Protocolos y Manuales facilitados por el fabricante serán aceptados como “Documentos Reconocidos” por el RITE.

Mano de obra

El contratista deberá acreditar el grado de capacitación y conocimiento que tiene el personal acerca de la fabricación de los conductos mediante un certificado de capacitación expedido por el fabricante. Para garantizar la calidad de los conductos, el equipo de herramientas utilizadas serán las facilitadas por el fabricante.

Armado y Sellado

Los conductos y las figuras se armarán con cuatro caras separadas biseladas longitudinalmente a 45° y se unirán usando pegamento adecuado. Las uniones longitudinales internas se sellarán con silicona adecuada hasta donde sea posible y en las externas se aplicará opcionalmente cinta de aluminio (obligatorio en los conductos instalados a la intemperie). Las uniones transversales entre las diferentes secciones de conductos se realizarán con el sistema de macho y hembra sellados con cinta de aluminio por el exterior. La cinta de aluminio deberá ser del mismo aluminio gofrado 60mµ que el de los paneles y la anchura mínima debe ser de 75mm (3”) e irá adherida con el mismo pegamento usado para el armado. Todos los insumos no originales utilizados deben ser consultados y aprobados por el fabricante. El procedimiento debe ser de acuerdo con los Protocolos y las recomendaciones facilitadas por el fabricante.

Refuerzos

Los conductos de suministro y/o de retorno deberán reforzarse internamente para soportar la presión de positiva y/o negativa de su funcionamiento y se deberá verificar su posicionamiento, intervalos y cantidad en función a la relación entre dimensión y presión.

Soportes, deflectores, puertas de inspección, pasos de muros, conexiones a unidades manejadoras, accesorios y restricciones.

Todos estos elementos deben ser instalados de acuerdo con el RITE y la norma europea EN 13403 y serán aplicados en base a los Protocolos y las recomendaciones facilitadas por el fabricante.

Conductos a la intemperie

Los conductos instalados a la intemperie serán de 30mm de espesor y la espuma PIR debe tener una densidad media de ±35 kg/m3 y cumplir así con el RITE. El aluminio gofrado de 60mµ de espesor en cada cara y con certificado de no proliferación microbiana.

Los conductos deberán ser lo más cuadrados posibles a fin evitar la acumulación de agua en la cara superior. Los conductos de anchura >120cm (48”) se dividirán en dos conductos para favorecer la resistencia mecánica. Independientemente de la presión de trabajo positiva o negativa, los conductos se reforzarán por el interior. Los tubos internos de refuerzo central se colocarán en posición vertical y se cortarán con una longitud de >1,5cm de la medida de la altura interior del conducto, para forzar la deformación en el centro del conducto de la cara superior hacia arriba y ayudar a escurrir el agua hacia los lados del conducto evitando la deformación y el deterioro por el peso del agua.

El armado de los conductos será el mismo que el aplicado para los conductos de 20mm instalados en el interior de los edificios y serán construidos en base a los Protocolos y recomendaciones facilitadas por el fabricante.

En aplicación del RITE, los conductos en el exterior deberán tener una protección adicional. Esta protección debe ser de pintura de base caucho impermeabilizante tipo “Sikafill” o “Sikafill 200 Fibras” de tres capas que se aplicará una vez terminados los trabajos de instalación de los conductos y evitar así cualquier filtración de agua hacia el interior de los conductos y del edificio.

Soportes y anclajes deberán evitar vibraciones y corrosiones garantizando la resistencia a los agentes meteorológicos: viento, lluvia, nieve, granizo, etc…

El procedimiento debe ser de acuerdo con los Protocolos y recomendaciones facilitadas por el fabricante.

Instalaciones en hospitales

Además de todo lo anterior mencionado, los conductos deberán cumplir con la EN 100713 para “Instalaciones de acondicionamiento del aire en los hospitales” y la EN 15780 de “Limpieza de sistemas de ventilación” así como las recomendaciones de la guía de ASHRAE “Hvac Desing Manual for Hospitals and Clinics”.

Protección antisísmica

Los soportes de los conductos serán conforme las recomendaciones de la “Practical Guide to Seismic Restraint” de ASHRAE.

| Description Characteristics | Galvanized Insulated Ductwork | PIRALU Pre-Insulated Duct System |

| Production | Sheet metal and Insulation materials plus glues and fastening accessories | Single source |

| Fabrication contamination | Fiberglass insulation dispersion during cutting may cause health problems. | No such dispersion as the material does not disintegrate while cutting. |

| IAQ compliance | In a warm and humid environment, wet fiber plus lagging adhesives used in insulation work give rise to eventual growth of fungus, bacteria, mildew (typical ‘black spots”). | Meets the requirement of IAQ (Indoor Air Quality) as per ASHRAE 62-1989 regulations, especially important in clean room applications such as hospitals, laboratories, food processing etc., public places such as malls and community centers. |

| Duct construction | Numerous vendors and components are required. Plus large on site fabrication requires bulky and expensive equipment and fabrication space. Plus additional time and materials for insulation. | Single Vendor and simple on site fabrication, can be done by one person with hand tools. Pre insulated duct boards save time and guarantee better thermal break control. |

| Weight | Galvanized sheets and specially the finished product is heavy, and usually requires a few persons for its transportation and installation. The heavier load requires more supports, and places a heavier tall on the building structure. | Light Weight (15%-20% of GI Ductworks). Less man power / Less fabrication time = $ savings Less weight = less man power / less possibility of accidents / less supports / less structural requirements |

| Heat Transfer | l= 0.038 (with 25mm thick insulation) | l = 0.023 w/mk Due to reduced losses, 18% energy savings over insulated GI ductwork |

| Fire codes | Class ‘O’, BS 476, part 6& 7. | Class ‘O’, BS 476, conforms to Building Regulations 1991. Tested and approved in most countries worldwide. ASTM E84 approved |

| Permeability, Solubility | Slightest damage to the aluminum foil vapor barrier causes condensation on duct surface, which will corrode ductwork and consequential damages to the building ceilings and structure. Fiberglass absorbs water and looses thermal properties. Damp and wet areas are susceptible to mildew and fungal growth. | Closed cell construction reduces water absorption to less than 5% in 24 hrs. of immersion. Slight site damages usually do not compromise the vapor barrier |

| Productivity | The cost of materials – metal and insulation – for typical low pressure air systems, in most (not all) markets tends to be 5-10% less than the pre-insulated panels. But the average waste is 10-15% in material | The FINAL installed cost of the same size of ductwork in pre-insulated material is approximately 20% – 25% less And the average waste is 3-5% |

| Mechanical Protection | In Outdoor systems most ductwork installation require an additional Mechanical protection, which is usually an aluminum cladding. | Pre-insulated panels already bring an aluminum cladding for protection and additional structural strength. |

| Exterior Painting | Usually a base primer is needed on canvas cladding. | Application of paint can be directly applied on panels due to its lacquered surface, which serves as base primer. |

| Reinforcements | Large duct cross sections require angle bracing at close intervals to avoid sagging due to weight of sheet metal and its insulation. | Not required for most common sizes; only extra-large sizes are recommended with stiffeners. A 20 mm thick panel will handle 50 Pa or 2” Wg |

Teksol offers different methods of supplying PIR-ALU products throughout Latin America:

- Direct factory to destination port under CIF incoterm

- From Miami in stock

Consult with your technical/commercial advisor for supply conditions, direct contact here: Sales.intl@teksolgroupsolutions.com

PRODUCT PRESENTATION

Description: Rigid panels of embossed aluminum sheet with PIR foam insulation. Applications:

Aplications: Manufacture of pre-insulated aluminum sheet ducts for air distribution and/or ventilation systems and air conditioning ducts.

advantages:

- Virtually zero water absorption, thanks to the closed-cell structure of the polymer and the aluminum sheet coating.

- Due to the thickness of the aluminum sheet (>60 µm), the product can be considered a vapor barrier.

- Panels with great rigidity and low weight.

- Easy handling, cutting, assembly, and installation.

Presentation:

|  |

SALES POLICIES

Consult with your technical/commercial advisor for supply conditions, direct contact here: Sales.intl@teksolgroupsolutions.com

Teksol applies a return policy of 20% on the total purchase after receiving the purchase order. For any specific situation, consult with your commercial advisor: Sales.intl@teksolgroupsolutions.com

- 852 panels

- Each panel represents: 3.6 m2

- Total M2 per 40HC container: 3067.2 m2

- 2 suitcases/boxes with cutting tools

- 320 liters of glue

- 312 units of silicone.

Partidas arancelarias (Schedule B / HS Code)

PARTIDA ARANCELARIA PANEL: 39219010

PARTIDA ARANCELARIA MALETIN:82055980

PARTIDA ARANCELARIA PEGAMENTO: 35069900

PARTIDA ARANCELARIA SILICONA: 39211900

BENEFITS

Los paneles producen provecho material, se ajustan a la realidad y son útiles aportando valor y beneficio a las redes de conductos. El Strip System enseña cómo hacerlo. La practicidad la aportan los materiales y sus prestaciones.

- THE MATERIALS

Respectful

Committed to the environment and health.

Ecological

It is an environmentally friendly product.

Eco-sustainable

It does not harm natural resources or the environment.

Easy to transport

Lightweight.

Easy to handle

Light and manageable

- PERFORMANCE

Insulating

Excellent thermal insulation.

Durable

Strong, resistant, and withstand the fatigue of their work.

Energy savings

Energy is money; do not spend more.

Safe

Free of risks.

Versatile

Suitable for all types of installations.

Hygienic and healthy

The air is always in contact with aluminum.

Comfortable

Material well-being and comfort.

The economy of a duct network begins with a simple and efficient design, then by using practical and efficient materials.

But above all, by applying a suitable system for transforming panels into ducts

Depending on the system applied, execution times, labor, materials, and waste increase or decrease.

The Strip System is the system proposed by PIR-ALU to transform pre-insulated aluminum panels into HVAC duct networks.

The Strip System is based on the standardization of dimensions and shapes. The standardized dimensions recommended by international standards or standards ISO 7807, EN 1505, or EUROVENT 2/3 are applied. The shapes of the pieces are those recommended by EN 12097.

EASY TO DESIGN Standard dimensions and shapes.

EASY TO EVALUATE THE COST The key to competitiveness is knowing the cost before starting work.

FÁCIL Y RÁPIDO DE ARMAR In practice, it is very similar to a DIY. (Do It Yourself)

QUICK TO INSTALL It installs quickly, requires few supports, and the ducts are assembled in sections of 3 or 6m in length. The finished duct weighs approximately 1.1kg/m².

NICE Once finished, the ducts are very pleasing to the eye, harmonious, and proportioned.

VERSATILE It can be installed inside and outside buildings. In hospitals, residential, commercial, industrial buildings, etc...

SAFE Free and free of risks. It meets the most demanding international requirements for mechanical strength and reaction to fire. It avoids any risk of condensation. All the benefits of materials and finished ducts are accredited with the required tests and certificates in the regulations, standards, or standards and certifications.

GREAT ENERGY SAVINGS The combination of excellent thermal insulation (λ=0.023 W/m·K declared according to 12667), low pressure drop (absolute roughness: 0.03mm), and the highest tightness rating for low and medium-pressure ducts (EN 1507: class "C") translates into savings of many kW of energy throughout the life cycle of the installation.

ECONOMIC It has a low cost and requires little expense.

FREQUENTLY ASKED QUESTIONS

El panel de aluminio Pre-aislado es un panel sándwich con dos láminas de aluminio puro gofrado y un aislamiento interno de espuma rígida de Poliisocianurato (PIR).

Intended for the construction of ducts for the distribution of air in ventilation, heating, and air conditioning installations (HVAC).

Paneles de Aluminio Pre-Aislados PIR-ALU

Pre-Insulated Aluminum Ducts PIR-ALU

The dimensions of the panels are: 3,000mm x 1,200mm

- Two different thicknesses: 20 and 30mm.

- The choice of thickness depends on the type of duct to be built.

- Small and medium sections: 20mm.

- Medium and large sections: 30mm.

- 20mm thick panels and 3,000mm long in packages of 12 panels

- 30mm thick panels and 3,000mm long in packages of 10 panels

- Packed in sturdy cardboard

It complies with current regulations in Spain, as well as in most countries in

With PIR-ALU panels, ducts are built that comply with the most demanding international standards, such as ASHRAE, SMAC

- Construct ducts with a length of 3,000mm.

- Always construct them with the four sides separated, regardless of shape and size.

- These sides are called "LATERALES."

- Air Quality: Always in contact only with aluminum – IAQ.

- Excellent Insulation: Thermal conductivity = 0.025 W/m.K.

- 3,000mm Long Ducts: Fewer transverse joints, faster to build and install.

- Total Tightness: Longitudinal and transverse joints sealed with glue and silicone on the interior.

- Weight: ±1.5 kg/m2, fewer supports (less labor and materials).

- Resilient: Light but robust.

- Four-sided Ducts: Sizes and pieces can be easily standardized.

- On-site Construction: Built directly at the construction site.

- Minimal Tools: Only two special tools required.

- Minimal Waste: Maximum material utilization and control.

- Easy to Construct: Accessible to any installer.

- Versatile Ducts: Suitable for any installation.

- No Limits: Correct application allows construction of ducts in any shape or size.

- Excellent Internal and External Finish: Embossed pure aluminum.

- Very Competitive Final Price.

- Innovation: Changing work habits.

- Preconceived Notions: Believing duct construction is artisanal and requires specialists.

- Indecision: Requires experimentation.

Anyone with minimal general experience in installations or familiarity with construction sites.

- Suitable for all types of installations: commercial, residential, industrial, or sanitary.

- Can be installed indoors (20mm thickness panel) or outdoors (30mm thickness panel).

- Not suitable for kitchen exhausts, chimney flues, or fumes saturated with chemicals.

- Not for transporting solid particles.

- Operating temperature range: -40ºC to +80ºC.

- Air speeds >15 m/s.

- Positive or negative pressure inside the duct exceeds:

20mm thickness panel: >1,000 Pa

30mm thickness panel: >1,400 Pa

Competitive pricing with both low-end (Mineral Fibers) and high-end (Insulated Sheet) markets.

- Very Practical:No need for specialists; can be constructed on-site to solve installation problems easily.

- Technical:Complies with national and international regulations.

- Excellent Insulation:Thermal conductivity = 0.025 W/m.K

- Robust:Manageable and resilient.

- Hygienic:Clean, as it is an aluminum duct.

- VERSATILECan be installed in any type of installation, both indoors and outdoors.

- ECONOMICVery competitive pricing with minimal tool investment.

- Easy to Find:Extensive network of distributors.

- HVAC installers seeking independence and increased competitiveness.

- Duct installers aiming for a qualitative leap in quality and competitiveness.

certificate

Privacy Policy

Welcome to Printful’s Privacy Policy!

TEKSOL, Inc. (“we”, “our”, “us”, or “Printful”) respects the privacy of its users and is fully committed to protect their personal data and use it in accordance with data privacy laws. This Privacy Policy describes how we collect, use, and process any personal data that we collect from you—or you provide to us—in connection with your use of our website (www. teksolgroupsolutions.com) or our mobile apps and our print-on-demand services (collectively, “Services”). By accessing or using our Services, you signify your understanding of the terms set out in this Privacy Policy.

We do not knowingly collect, maintain, disclose, or sell the personal information about users under the age of sixteen (16). If you are under the age of 16, please do not use our Services. If you are under the age of 16 and have used our Services, please contact us at the email address below so that we may delete your personal information.

If you use our Services only for your personal use, you are to be considered as the “User” and for the purpose of the General Data Protection Regulation (“GDPR”), we are the data controller.

If you use our Services to execute orders and deliver products to third parties, you are to be considered as the “Merchant” and with regard to your contact details and the other data listed in Section 1 below, we are the data controller. Where we act on a Merchant’s behalf to fulfil an order with regard to the Merchant’s customer, we are a data processor.

Note that while our Services may contain links to other websites or services, we are not responsible for each respective website’s or service’s privacy practices and encourage you to be aware of this when you leave our Services and carefully read the privacy statements of each and every website and service you visit. This Privacy Policy does not apply to third-party websites and services. If you wish to contact Printful regarding your personal data or this Privacy Policy, please contact us at sales.int@teksolgroupsolutions.com

services

FREE AIR DUCT PLAN READING SERVICE, MAXIMIZING YOUR PANEL USAGE AND PROVIDING AN EASY-TO-USE GUIDE FOR CUTTING AND INSTALLATION.

Reading and optimization of the duct system:

- 1. Material calculation

- 2. Waste reduction

Send us your AutoCAD drawings, and we will prepare a personalized report for you. Sales.intl@teksolgroupsolutions.com